When you think of 3D printing, you probably imagine a structure being created layer by layer, from the bottom up. Now, researchers from Switzerland's Ecole polytechnique fédérale de Lausanne (EPFL) say they have developed a completely new way of creating 3D objects that offer remarkable resolution "in record time."

As EPFL News reports, the method draws on the principle of tomography -- the technique for displaying a representation of a cross section through a solid object, using x-rays or ultrasound. To make an object, a photosensitive resin is illuminated from multiple angles, with the accumulation of light helping to solidify the resin. In other words, the object forms a solid structure within the resin in one go, rather than segment by segment, as is the case with traditional 3D printing.

"It's all about the light," explains Paul Delrot, CTO of Readily3D, the company that has been set up to develop and market the system. "The laser hardens the liquid through a process of polymerization. Depending on what we're building, we use algorithms to calculate exactly where we need to aim the beams, from what angles, and at what dose."

The technology could have a wide range of uses, but its advantages over existing methods may assist medical experts. Researchers believe the process could be used, for instance, to make soft objects such as "tissue, organs, hearing aids and mouthguards." What's more, printing can take place inside sealed, sterile containers, preventing contamination.

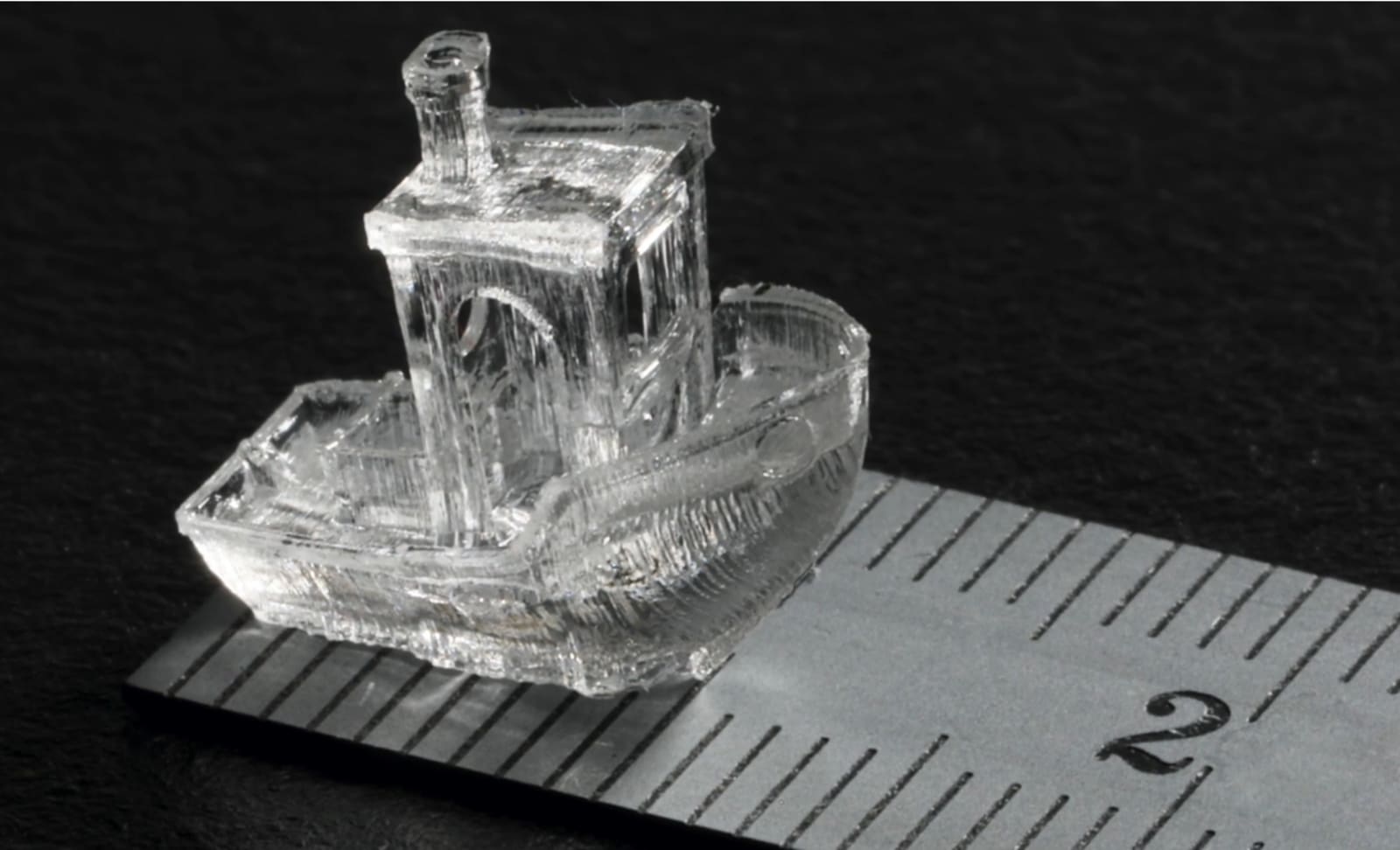

"The system is currently capable of making two-centimeter structures with a precision of 80 micrometers, about the same as the diameter of a strand of hair," EPFL News adds. However, the team believe that could be increased to 15 centimeters in the future. "The process could also be used to quickly build small silicone or acrylic parts that don't need finishing after printing," says Christophe Moser, head of EPFL's Laboratory of Applied Photonics Devices.

Update - 12:15pm ET 02/13/2020: This article has been updated to better clarify the source of the research detailed by the Ecole polytechnique fédérale de Lausanne (EPFL).

Via: EPFL

Source: Nature

by: via https://www.AiUpNow.com/